Commercial Concrete Services in Friendswood TX Built to Perform

Structural Commercial Concrete for Industrial & Commercial Builds

At Concrete Commandos, we specialize in delivering commercial concrete solutions that meet the rigorous demands of structural integrity, durability, and safety in Friendswood, TX. Whether you're constructing tilt-up concrete walls, heavy-duty loading docks, or parking lots that handle thousands of pounds of traffic per day, our team is equipped to deliver. We use high PSI concrete mixes, precision-placed rebar, and engineered expansion joints to ensure every commercial slab is structurally sound and built to last.

Call 346-550-9994 now to schedule a commercial concrete

quote in Friendswood and see why developers and general contractors rely on us.

Get In Touch With Us!

Parking Lot Installation and Replacement

Concrete parking lots are more than a surface they’re an investment in safety and performance. We build lots with longevity in mind, using sub-base compaction, proper control joints, and high-strength concrete mixes rated for Texas heat. Every project includes:

Layout and striping per ADA requirements

Expansion joint placement for movement

Curb and gutter systems

Optional sealing for UV and chemical resistance

Long-term durability with minimal maintenance

Specialized Commercial Concrete Solutions

When it comes to commercial construction, not all concrete is created equal. The requirements for load-bearing capacity, thermal performance, and surface resilience demand specialized expertise. Our services are engineered for everything from retail plazas to industrial plants, and we offer core capabilities tailored to today’s commercial needs.

Tilt Wall Construction

Tilt-up concrete is one of the most efficient methods for erecting large commercial buildings. We cast concrete panels on-site or off-site, cure them to full strength, and lift them into position using a crane. This method cuts down on timeline and cost while increasing structural rigidity.

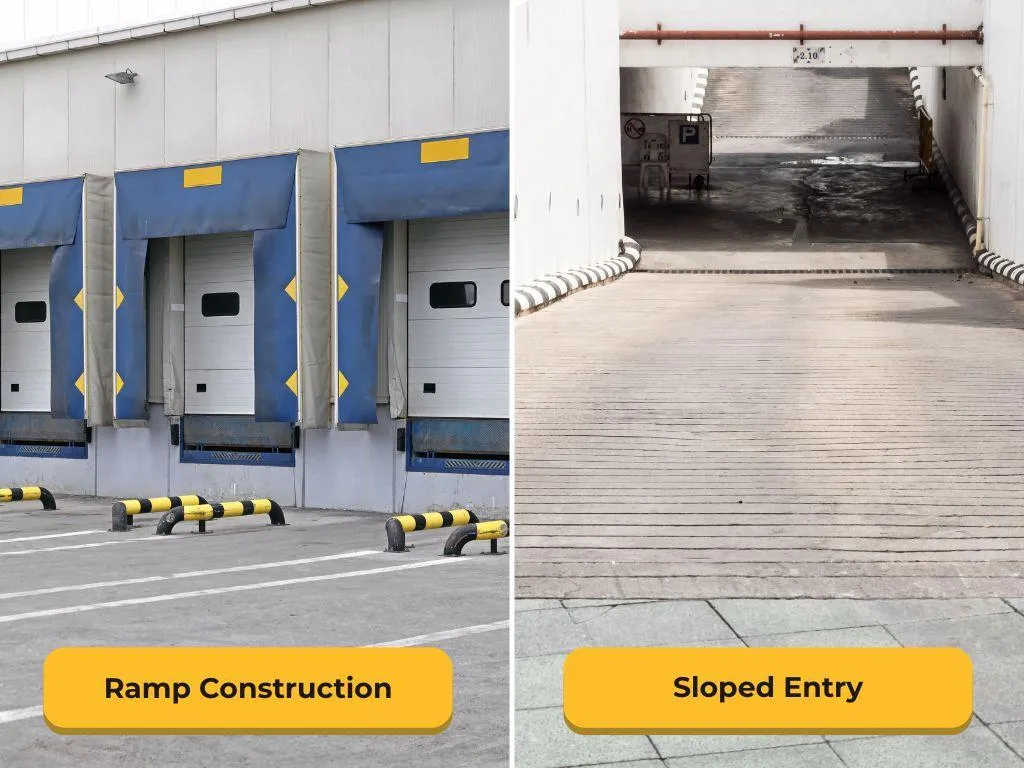

Concrete Well Docks and Loading Areas

A properly installed concrete well dock is essential for logistics efficiency. These recessed loading zones are built to accommodate semi-trailers and forklifts, requiring precise formwork and heavy reinforcement. We install:

Retaining walls, dock ramps, and edge curbs

Steel-reinforced slabs to handle heavy axle loads

Grooved finishes for traction during rain

Bollards and bumpers for impact control

Drainage slopes to prevent water pooling

Engineered Drainage and Sloping

Without proper drainage, concrete surfaces will fail early. Our team designs each slab with:

Edge drainage and trench systems

Surface grading that directs water flow

Tie-ins to stormwater infrastructure where applicable

Built for Friendswood’s Climate and Soil Conditions

South Texas weather and soil present unique challenges. Our work in Galveston County has taught us how to anticipate movement, moisture, and temperature extremes in every commercial slab.

Dealing with Expansive Clay Soils

Friendswood sits on expansive clay, which shrinks and swells with moisture changes. To mitigate this, we use:

Reinforced structural slabs

Moisture barriers and treated base layers

Deeper footings and increased dowel anchoring

High Heat and Rainfall Tolerance

Summers here are long and hot, often followed by heavy rainfall. We adjust by:

Pouring at cooler times of day

Using PSI mixes rated for rapid cure and heat exposure

Designing slopes for efficient runoff

Concrete Tilt-Up Wall Construction

Fast-Track Structural Concrete Walls

Tilt-up construction is a method where concrete elements are cast on-site and then lifted into position, offering a cost-effective and time-efficient alternative to traditional building methods. This technique is widely used in North America for various types of buildings, including warehouses and retail centers.

Engineered Panel Layout & Casting On-Site

Each tilt panel is formed with rebar grids and poured flat on curing slabs. Once cured, a crane lifts them vertically and secures them to the slab using precision brackets and anchors.

Ideal for Warehouses, Retail Boxes, and Industrial Parks

Common in industrial architecture, tilt walls are a preferred solution for distribution centers, gyms, and retail showrooms. They combine rapid installation with structural strength and fire resistance.

What’s Included in a Commercial Concrete Project

From site prep to final inspection, our process is tailored for efficiency, safety, and long-term performance. Every detail matters when you're pouring commercial concrete.

Site Prep and Excavation

We begin with:

Digital layout and laser-guided marking

Excavation to engineered depths

Base compaction with crushed rock and soil stabilization

Formwork and Reinforcement

Next, we set up forms with:

Custom dimensions based on load calculations

Steel rebar cages and mesh reinforcement

Anchor bolts, embedded conduits, and sleeves where required

Concrete Pour and Finishing

We pour at optimal PSI levels, screed the surface, and apply the finish based on project type:

Broom or trowel finish

Slip-resistant textures for ADA or warehouse use

Saw-cut control joints

Edge smoothing and corner hardening

Post-Pour Quality Checks

Once poured, we monitor the curing process, maintain moisture levels, and complete:

Surface inspection for cracking or delamination

Drainage function tests

ADA and city code compliance checks

Types of Commercial Projects We Handle

From Fortune 500 warehouse buildouts to local retail parking lots, we handle commercial concrete projects of all sizes. Our portfolio includes:

Tilt wall structures for logistics and fulfillment centers

Drive lanes and loading bays for industrial parks

Retail center parking lots and drive-thru slabs

Equipment pads for HVAC or heavy machinery

ADA-compliant walkways and curbing for medical and municipal buildings

If it supports business traffic, weight, or infrastructure we build it.

Our Commercial Concrete Installation Process

Our installation process is both time-tested and compliant with local engineering standards.

Consultation and Planning

We begin with a detailed consultation, including:

Soil assessments and structural calculations

Engineering coordination

Scheduling and staging logistics

Engineering and Permitting

We manage:

Blueprints and stamped plans

City of Friendswood permit filing

Utility locate and pre-pour inspections

Excavation and Subgrade Prep

Next, we:

Clear and demo existing slabs (if applicable)

Compact soil and add base rock

Level and shape the subgrade

Pouring and Structural Work and Finishing

Our crews:

Build forms and install reinforcement

Pour concrete using mixers on-site

Monitor elevation and slope throughout the pour

Why General Contractors and Property Owners Trust Us

We’ve built our reputation on performance, consistency, and transparency. Our team has over 30 years of combined experience in concrete construction, project management, and site engineering.

We don’t use subcontractors every project is done by trained in-house crews

We understand Friendswood’s local codes, soil maps, and zoning setbacks

We keep permits and inspections on schedule so you can hit your deadlines

We’ve earned 5-star ratings from builders and developers across Forest Bend, West Ranch, and the greater Galveston County region

How it works

Get a Free Quote

Call us at 346-550-9994 or fill out our short form to request a free estimate. One of our team members will reach out to schedule a time to check out your concrete project needs.

Receive an Estimate

After we assess the job, you'll get a written estimate with the details and cost. Just reply to confirm, and we’ll arrange a time that works best for you to get the job done.

Complete the Job

Our professional crew will arrive on the scheduled date, complete the project, clean up any debris, and leave your property looking great!

Concrete Contractor

SERVICES We Offer

Serving Commercial Clients Across Friendswood and Harris

Our team proudly serves commercial construction projects in:

Friendswood

Forest Bend

West Ranch

Eagle Lakes

Heritage Park

Mission Estates

Things To Do In Friendswood

Project Gallery

testimoniAls

Frequently Asked Questions About Concrete Driveways in Friendswood

What PSI concrete do you use for commercial slabs?

Most of our commercial projects use 4000–5000 PSI mixes depending on load. We adjust mixes for tilt walls, parking lots, or well docks as needed.

How long does a commercial concrete project take?

Small jobs like parking lot replacements may take 2–3 days. Tilt wall and dock installations usually take 1–2 weeks including cure time and inspections.

Are your concrete slabs ADA compliant?

Yes. We follow all ADA slope, width, texture, and clearance guidelines on commercial walkways, ramps, and parking spaces.

Can you integrate plumbing and conduit into commercial pours?

Absolutely. We coordinate closely with other trades to embed piping, electrical conduits, or anchor systems into the pour.

Do you offer maintenance services for commercial concrete?

Tilt-up panels are cost-effective, fast to install, and extremely strong. They’re great for buildings with large floor plans and fast build cycles.

How do I get a commercial concrete estimate?

We offer crack repair, resealing, and surface rejuvenation for older commercial slabs to extend lifespan and maintain appearance.

Need Commercial Concrete Company in Friendswood?

GET YOUR FREE ESTIMATE TODAY!

Contact Info

Address

1560 W Bay Area Blvd #405, Friendswood, TX 77546

Phone

Service Hours

Monday-Friday 8:00AM-5:00PM

Copyright 2026 / Concrete Commandos Friendswood / All Rights Reserved

This site is a service to assist homeowners in connecting with local service contractors. All contractors are independent and this site does not perform, not warrant or guarantee any work done by the contractor you engage. It is the responsibility of the property owner to verify that the hired contractor furnishes the necessary license and insurance required for the work being performed.